3D封装之TSV工艺总结

以下文章来源于半导体百科 ,作者John H. Lau

半导体集成电路视频与博文分享,打造最有技术价值的分享频道

转载自半导体百科

作者:John H. Lau

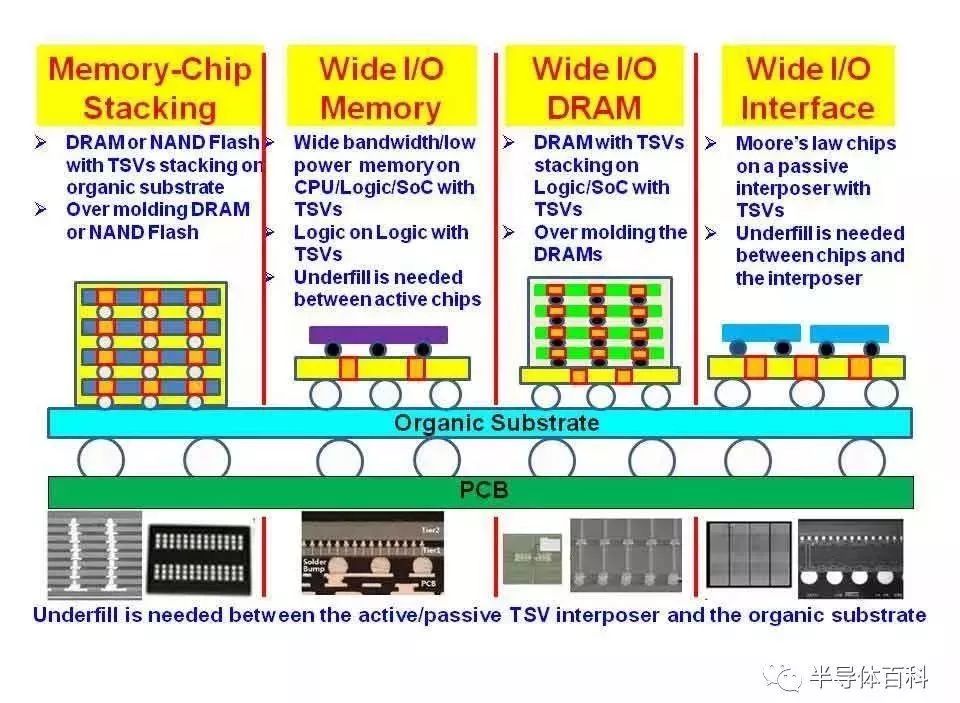

图1:Potential application and high-volume manufacturing of 3D IC integration

存储芯片堆叠

图1最左端图示是Samsung公司在2006年发布的最简单的存储芯片堆叠示意图。这些芯片可能是DRAM(动态随机存取存储器)或I/O数量少于100的NAND闪存(确切地说是78个)。很重要的一点是,这种存储芯片附在有机基板上,即使采用八个芯片堆叠,它们的总厚度(560μm)仍小于普通芯片的厚度。遗憾的是,由于成本问题和引线键合技术的竞争,使用TSV(Through Silicon Via,硅通孔技术)的存储器芯片堆叠目前尚未针对消费产品进行批量生产。目前,Samsung正在开发的下一代服务器产品,很可能考虑采用DDR4(双信道四次同步动态随机存取内存)SDRAM(同步动态存储器)。

宽I / O存储或逻辑堆叠

宽I / O DRAM(HMC)

无源转接板的宽I / O接口(2.5DIC封装)

TSV时代之前的技术流程

TSV时代的技术流程

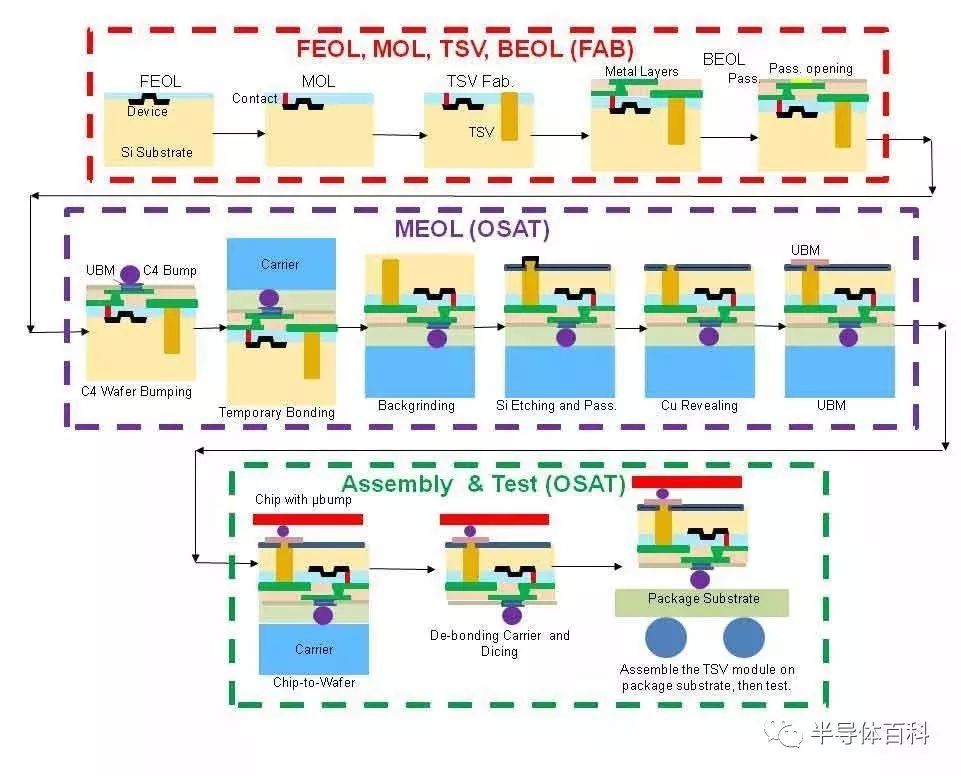

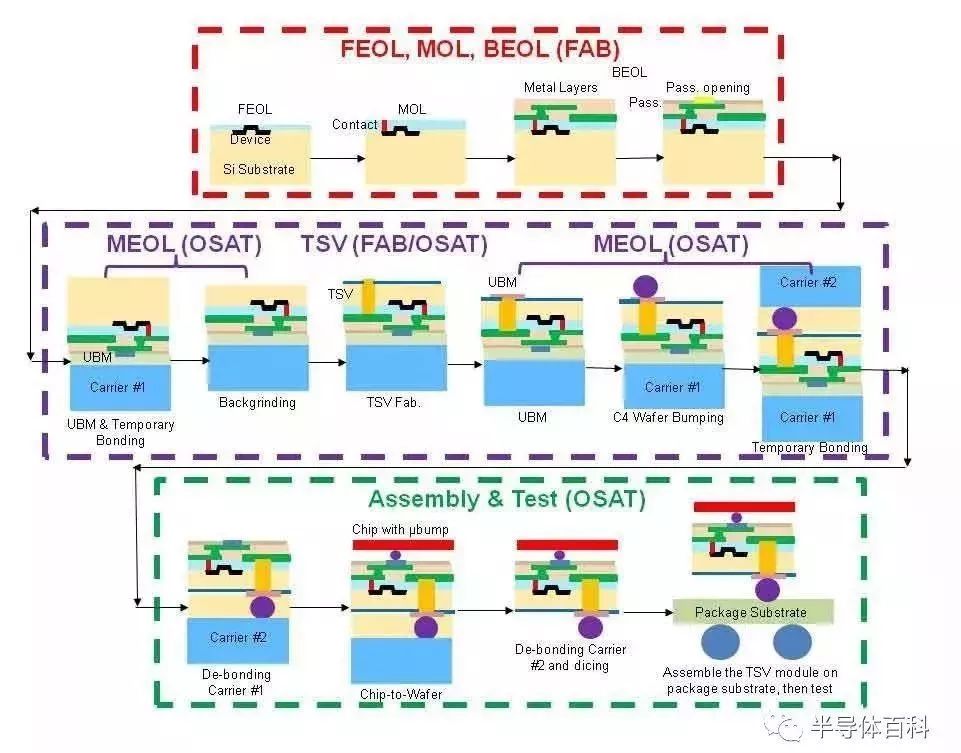

图2:Critical steps and ownerships for (face-to-back) wide I/O memory using the TSVvia-middle fabrication process.

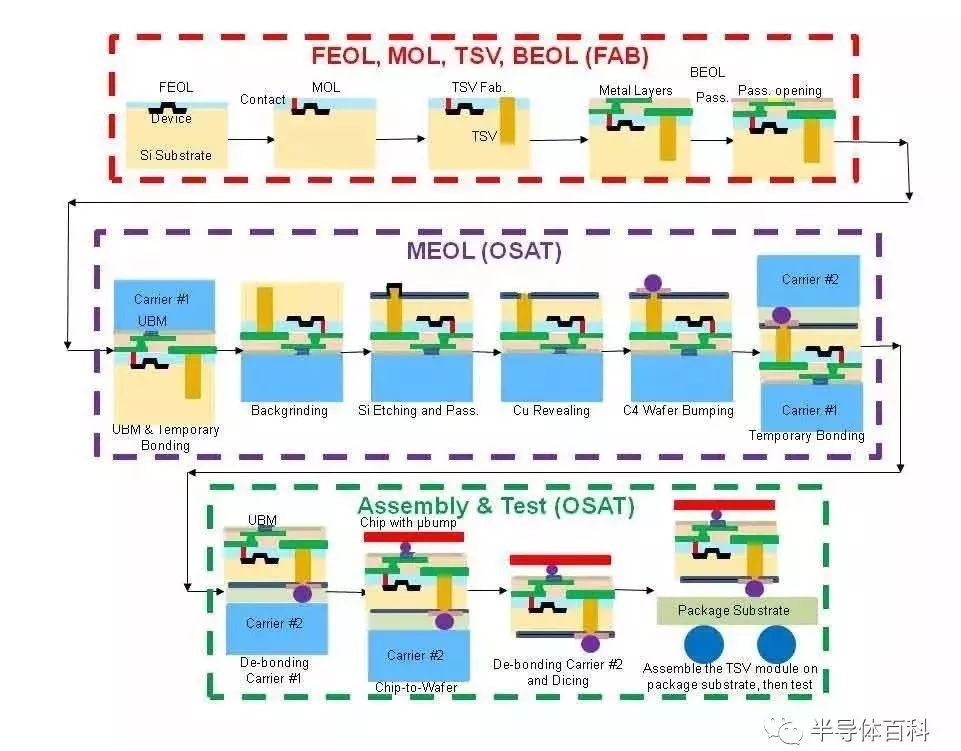

图3:Critical steps and ownerships for (face-to-face) wide I/O memory using the TSVvia-middle fabrication process.

B)谁负责MEOL工艺

对于HMC中DRAMs和存储.芯片堆叠的厚度,以及考虑到有源和无源转接板的厚度,所有制造的TSV都是盲孔。盲孔TSV工艺之后是焊料凸点/临时粘合/减薄/ TSV露点/薄晶圆支撑转移/剥离/清洁,这些过程统称为MEOL(生产线的中端)。对于这项工作,除了纵向一体化公司公司(例如,TSMC和Samsung集团),最好由OSAT完成MEOL流程。

C)量产3D封装的关键步骤分工

C.1)TSV Via-Middle工艺制造宽I / O存储器(面对背):图2显示了该工艺的关键步骤和制备工厂。在FEOL(用于对器件进行图案化)和MOL(用于形成金属接触)之后,通过五个关键步骤制造TSVs,即通孔制造。通孔是由深反应等离子蚀刻形成的(DRIE),电介质是通过等离子体增强化学气相沉积的(PECVD),阻挡层和种子层通过物理气相沉积(PVD),使用电镀铜填充和化学机械抛光(CMP)去除覆盖的铜。这些步骤之后是金属层的堆积,最后是钝化/开口(BEOL)。所有这些步骤都应在fab中完成。

C.2)TSV Via-Middle工艺制造宽I / O存储器(面对面):FEOL,MOL,TSV和BEOL过程与TSV via-middle(面对背)工艺流程完全相同。但是,接下来的工艺流程是不同的。TSV晶片不是在UBM后使用C4技术焊接到载体晶片上,而是临时连接到载体#1。然后,对TSV晶片进行背面研磨,并完成Cu显露和UBM。这些步骤之后进行C4工艺,并临时粘合到第二个载体#2。然后,将载体#1从TSV晶片上剥离下来,并进行C2W(面对面)键合。在C2W键合之后,将载体#2从TSV晶片上剥离。随后将TSV晶片切成单独的TSV模块。将该TSV模块回流焊接到封装基板上,然后进行测试。关键步骤如图3所示。

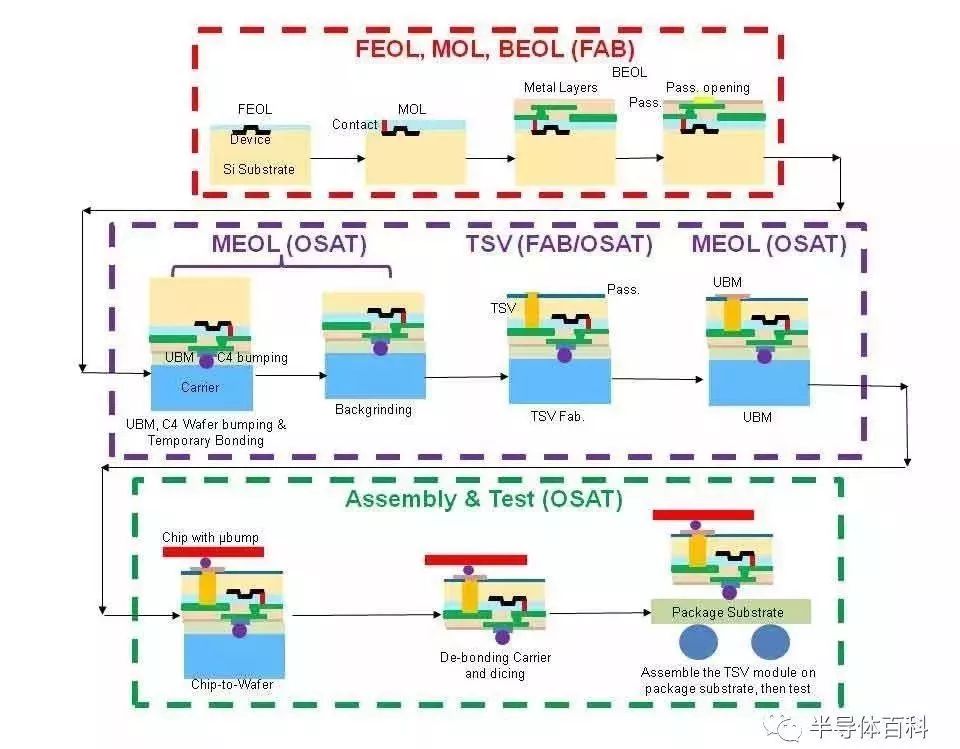

C.3)TSV Via-Last工艺(从背面)制造宽I / O存储器(面对背):图4显示了该工艺的关键步骤和制备工厂。在FEOL(对器件进行图案化),MOL(形成金属接触)和BEOL(构建金属层以及钝化/开口)之后进行UBM制备和C4工艺。然后,将该结构临时和载体晶片键合。再进行背面研磨,TSV制造和钝化/开口以及UBM。

C.4)TSV Via-Last工艺(从背面)制造宽I / O存储器(面对面):FEOL,MOL和BEOL工艺与和面对背TSV via-last(从背面)过程完全相同。但是,对于面对面情况而言,在UBM步骤之后,器件晶片临时粘合到载体#1如图5所示。然后,对背面进行背面研磨,TSV加工和钝化/开口处理。在这些过程之后,制备UBM,进行C4工艺,并临时粘合至载体#2。然后完成与载体#1的剥离。

图5:Critical steps and ownerships for (face-to-face) wide I/O memory using the TSVvia-last from the backside fabrication process.

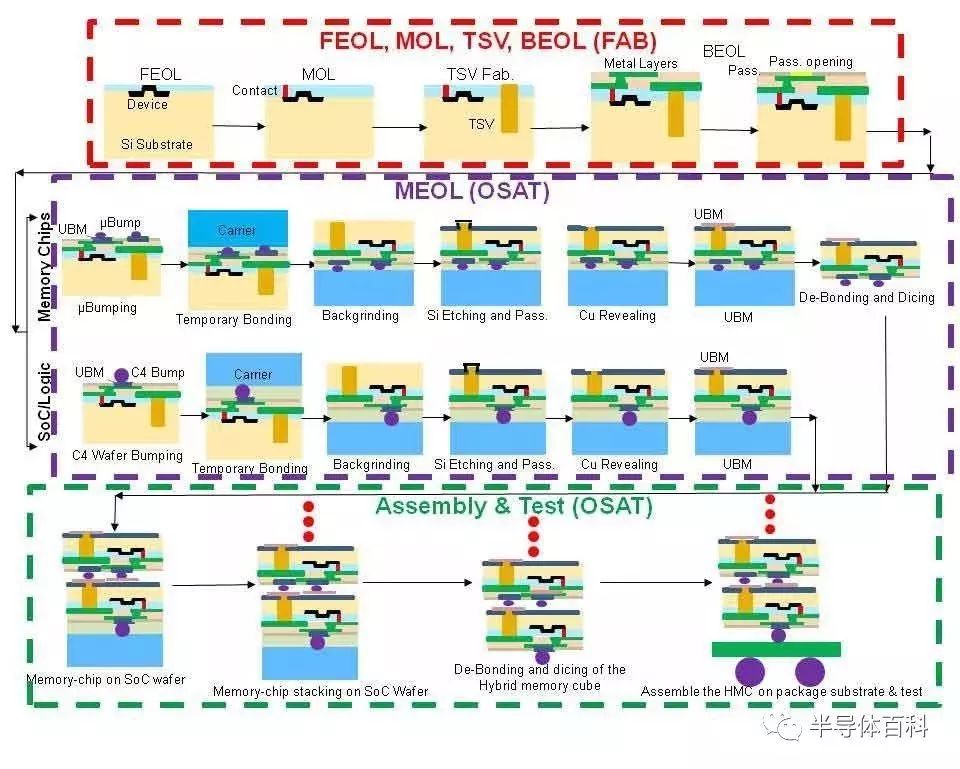

C.5)TSV Via-Middle工艺制造宽I / O DRAM:在DRAM和SoC/logic晶片的FEOL,MOL,TSV和BEOL之后,SoC /logic晶圆将按照图2(C.1)所示的面对背,或图3 (C.2)面对面工艺步骤进行操作。对于DRAM,首先要进行UBM,然后是整个晶圆的微凸点工艺。在这些过程之后,将临时粘合到载体晶片,进行背面研磨减薄,铜暴露和UBM。再依次进行载体晶圆剥离和将TSV DRAM晶圆切成单个TSV DRAM芯片,如图6所示。

图6:Critical steps and ownerships for wide I/O DRAM using the TSV via-middlefabrication process.

C.6)TSV Via-Middle工艺制造宽储存器芯片堆叠:存储器芯片(DRAM或NAND闪存)堆叠的关键步骤和制备工厂与宽I / O DRAM情况完全相同,如图6(C.5)所示。然而,不同于宽I / O DRAM情况下采用C2W键合,内存芯片堆叠是通过首先堆叠各个TSV芯片然后将它们连接到封装基板上并且采用灌胶成型来实现的。在这些步骤之后,将TSV存储器芯片堆叠模块连接到印刷电路板上,例如双列直插式存储器模块(RDIMM)。

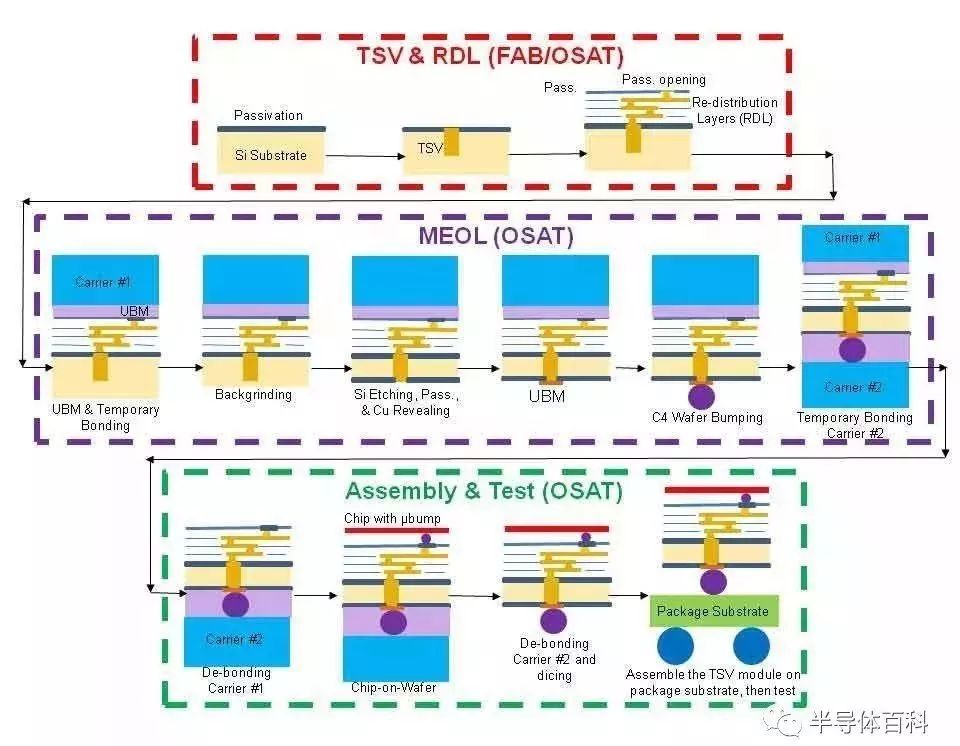

C.7)2.5D IC封装技术制备TSV / RDL无源转接板:图7显示了关键步骤和制备工厂。在一块dummy硅(无有源器件)上沉积钝化层之后,制作TSV,构建RDL并进行钝化/开口。在UBM之后,将TSV晶片临时粘合到载体#1。然后进行背面研磨,硅蚀刻,低温钝化和铜暴露。其后,完成UBM,C4工艺以及与载体#2的临时粘合。不带TSV的器件晶圆分别用微焊料凸点或带有焊帽的Cu柱对存储器晶片进行微凸点处理。再将器件晶片切成有微凸点/Cu柱的单个芯片。

图7:Critical steps and ownerships for 2.5D IC integration with a TSV/RDL passiveinterposer.

总结

参考文献:

J. H. Lau., Through-Silicon Via for 3DIntegration, McGraw-Hill Book Company, New York, NY, 2012.

U. Kang, H. Chung, S. Heo, D. Park, H.Lee, J. Kim, et al., "8 Gb 3-D DDR3 DRAM Using Through-Silicon-ViaTechnology," IEEE Journal of Solid-State Circuits, Vol. 45, No. 1, Jan.2010, pp. 111-119.

P. Dorsey, "Xilinx Stacked SiliconInterconnect Technology Delivers Breakthrough FPGA Capacity, Bandwidth, andPower Efficiency," Xilinx White Paper: Virtex-7 FPGAs, WP380, Oct. 27,2010, pp. 1-10.

B. Banijamali, S. Ramalingam, K.Nagarajan, R. Chaware, "Advanced Reliability Study of TSV Interposers andInterconnects for the 28nm Technology FPGA," IEEE ECTC Proc., Orlando,Florida, June 2011, pp. 285-290.

R. Chaware, K. Nagarajan, S.Ramalingam, "Assembly and Reliability Challenges in 3D Integration of 28nmFPGA Die on a Large High Density 65nm Passive Interposer," Proc. ofIEEE/ECTC, May 2012, pp. 279-283.

B. Banijamali, S. Ramalingam, H. Liu,M. Kim, "Outstanding and Innovative Reliability Study of 3D TSV Interposerand Fine Pitch Solder Micro-bumps," Proc. of IEEE/ECTC, May 2012, pp.309-314.

A. Redolfi, D. Velenis, S. Thangaraju,P. Nolmans, P. Jaenen, M. Kostermans, et al., "Implementation of anIndustry Compliant, 5x50µm, Via-Middle TSV Technology on 300mm Wafers,"Proc. of IEEE/ECTC, Orlando, Florida, June 2011, pp. 1384—1388.

M. G. Farooq, T. L. Graves-Abe, W. F. Landers,C. Kothandaraman, B. A. Himmel, P. S. Andry, et al., "3D Copper TSVIntegration, Testing and Reliability," Proc. of IEEE/IEDM, Washington DC,Dec. 2011, pp. 7.1.1 — 7.1.4.

H. Chaabouni, M. Rousseau, P. Ldeus, A.Farcy, R. El Farhane, A. Thuaire, et al., "Investigation on TSV impact on65nm CMOS devices and circuits," Proc. of IEEE/IEDM, Dec. 2010, pp. 35.1.1- 35.1.4. [10] Y. C. Hsin, C. Chen, J.H. Lau, P. Tzeng, S. Shen, Y. Hsu, et al., "Effects of Etch Rate onScallop of Through-Silicon Vias (TSVs) in 200mm and 300mm Wafers," IEEEECTC Proc., Orlando, Florida, June 2011, pp. 1130-1135.

C. Wu, S. Chen, P. Tzeng, J. H. Lau, Y.Hsu, J. Chen, et al., "Oxide Liner, Barrier and Seed Layers, andCu-Plating of Blind Through Silicon Vias (TSVs) on 300mm Wafers for 3D ICIntegration," IMAPS Trans., Jour. of Microelectronic Packaging, Vol. 9,No. 1, First Quarter 2012, pp. 31-36. J. C. Chen, J. H. Lau, P. J. Tzeng,S. Chen, C. Wu, C. Chen, et al., "Effects of Slurry in Cu Chemical MechanicalPolishing (CMP) of TSVs for 3-D IC Integration," IEEE Trans. on CPMT, Vol.2, No. 6, June 2012, pp. 956-963.

W. Tsai, H. H. Chang, C. H. Chien, J. H.Lau, H. C. Fu, C. W. Chiang, "How to Select Adhesive Materials forTemporary Bonding and De-Bonding of Thin-Wafer Handling in 3D ICIntegration," IEEE ECTC Proc., Orlando, Florida, June 2011, pp. 989-998.

H. Chang, J. H. Lau, W. Tsai, C. Chien, P.Tzeng, C. Zhan, et al., "Thin Wafer Handling of 300mm Wafer for 3D ICIntegration," 44th International Symp. on Microelectronics, Long Beach,CA, Oct. 2011, pp. 202—207.

A. Jourdain, T. Buisson, A. Phommahaxay,A. Redolfi, S. Thangaraju, Y. Travaly, et al., "Integration of TSVs, waferthinning and backside passivation on full 300mm CMOS wafers for 3D applications,"Proc. of IEEE/ECTC, Orlando, Florida, June 2011, pp. 1122 — 1125.

C. K. Lee, T. C. Chang, J. H. Lau, Y.Huang, H. Fu, J. Huang, et al., "Wafer Bumping, Assembly, and Reliabilityof Fine-Pitch Lead-Free Micro Solder Joints for 3-D IC Integration," IEEETrans. on CPMT, Vol. 2, No. 8, Aug. 2012, pp. 1229-1238.

V. Rao, X. Zhang, S. Ho, R. Rajoo, C.Premachandran, V. Kripesh, et al., "Design and Development of Fine PitchCopper/Low-k Wafer Level Package," IEEE Trans. on Advanced Packaging, Vol.33, No. 2, May 2010, pp. 377—388.

J. H. Lau, C. J. Zhan, P. J. Tzeng, C. K.Lee, M. J. Dai, H. C. Chien, et al., "Feasibility Study of a 3D ICIntegration System-in-Packaging (SiP) from a 300mm Multi-Project Wafer(MPW)," IMAPS Trans., Jour. of Microelectronic Packaging, Vol. 8, No. 4,Fourth Quarter 2011, pp. 171-178.

C.Zhan, P. Tzeng, J. H. Lau, M. Dai, H. Chien, C. Lee, et al., "AssemblyProcess and Reliability Assessment of TSV/RDL/IPD Interposer withMulti-Chip-Stacking for 3D IC Integration SiP," IEEE/ECTC Proc., SanDiego, CA, May 2012, pp. 548-554.

S. Sheu, Z. Lin, J. Hung,, J. H. Lau, P.Chen, et al., "An Electrical Testing Method for Blind Through Silicon Vias(TSVs) for 3D IC Integration," IMAPS Trans., Jour. of MicroelectronicPackaging, Vol. 8, No. 4, Fourth Quarter 2011, pp. 140-145.

J. F. Hung, J. H. Lau, P. Chen, S. Wu, S.Lai, M. Li, et al., "Electrical Testing of Blind Through-Silicon Via (TSV)for 3D IC Integration," IEEE/ECTC Proc., San Diego, CA, May 2012, pp.564-570.

J. Chien, Y. Chao, J. H. Lau, M. Dai, R.Tain, M. Dai, et al., "A Thermal Performance Measurement Method for BlindThrough Silicon Vias (TSVs) in a 300mm Wafer," IEEE ECTC Proceedings,Orlando, Florida, June 2011, pp. 1204-1210.

本文由IC字幕组 辰 翻译自2014年ChipScaleReview第三期 ,Gab校对修改

扫一扫下载订阅号助手,用手机发文章

扫一扫下载订阅号助手,用手机发文章